Synopsis

Post‑accident frame inspections are critical because even minor collisions can shift structural points, weaken safety systems, and affect how your vehicle protects you in another crash. Redeemed Auto Body explains how hidden damage occurs, why OEM‑based measuring matters, and how a proper structural evaluation makes sure your vehicle drives and safeguards you the way it should.

Modern vehicles depend on precise structural alignment to protect you during a collision. When you need auto collision repair services, understanding the importance of frame inspection can help you make informed decisions about your vehicle’s safety. Even a small impact can shift critical points in the frame, weaken engineered crash structures, and interfere with built-in safety systems. When drivers search for collision repair near them, they often think only about fixing dents or cosmetic issues. The real risk, however, hides beneath the surface. Redeemed Auto Body wants you to understand why frame inspections matter for your safety, your vehicle’s performance, and long-term value. Our collision center in West Monroe, LA, is a one-stop destination for all your auto body repair needs.

A proper structural evaluation is one of the most important steps after any accident, no matter how minor it may seem. You deserve repairs that support the way your vehicle was designed to respond in a crash, and our goal is to help you make informed decisions every step of the way.

What a Vehicle Frame Actually Does After a Collision

A vehicle’s frame forms the foundation that supports its entire structure. It is designed to absorb impact forces, maintain cabin integrity, and work with modern technology that protects you during a crash. Most vehicles today are built using a unibody structure, which means the frame and body are engineered as one system instead of separate components.

Unibody design improves ride quality and crash absorption, but it also makes accurate structural measurements essential for quality collision repair. If key points shift even a few millimeters, the change can affect how the vehicle handles or how energy moves through the structure during another accident.

Your frame also connects to several critical safety systems:

- Airbags: Deployment timing depends on precise sensors mounted to the structure. Misalignment can affect their performance.

- Crumple Zones: These engineered sections must deform in a controlled way to reduce the force transferred to you.

- ADAS Features: Modern driver-assist systems rely on mounted sensors, cameras, and radar units that require accurate alignment.

When the frame is compromised, the entire safety ecosystem becomes less reliable. This is why our team at Redeemed Auto Body treats structural evaluation as the foundation of proper auto collision repair.

Why Hidden Frame Damage Is Common After an Accident

Many drivers assume frame damage only occurs in major accidents. In reality, hidden structural shifts can occur even in low-speed collisions. Industry studies and biomechanics research point to meaningful forces and possible structural or occupant effects at roughly 10 to 15 km/h (about 6 to 9 mph), so a seemingly minor collision can still cause unseen damage. Bumper covers, fenders, and plastic panels can mask deeper issues, giving the impression that a collision was only cosmetic.

Here are a few examples of impacts that often cause unseen structural changes:

- Rear bumper hit: The outer cover may flex back into place while the underlying rails bend.

- Side impact: A door or quarter panel may show minimal damage, yet the rocker panels absorb force.

- Front corner hit: The apron, core support, or upper rails can shift even when the hood still appears straight.

When a vehicle’s frame is even slightly misaligned after a collision, it can no longer absorb and distribute crash forces the way the manufacturer designed it to. This structural compromise weakens the vehicle’s ability to protect occupants in a subsequent accident. That is why we use professional 3D measuring systems (for example, Spanesi 3D measuring equipment or an equivalent OEM-capable system) and compare readings to manufacturer specifications to verify repairs meet OEM tolerances. Small changes in alignment lead to large changes in crash response.

Hidden issues become even more common in modern vehicles because manufacturers use lightweight materials such as high-strength steel and aluminum. These materials transfer impact energy more efficiently, which means forces travel farther through the structure.

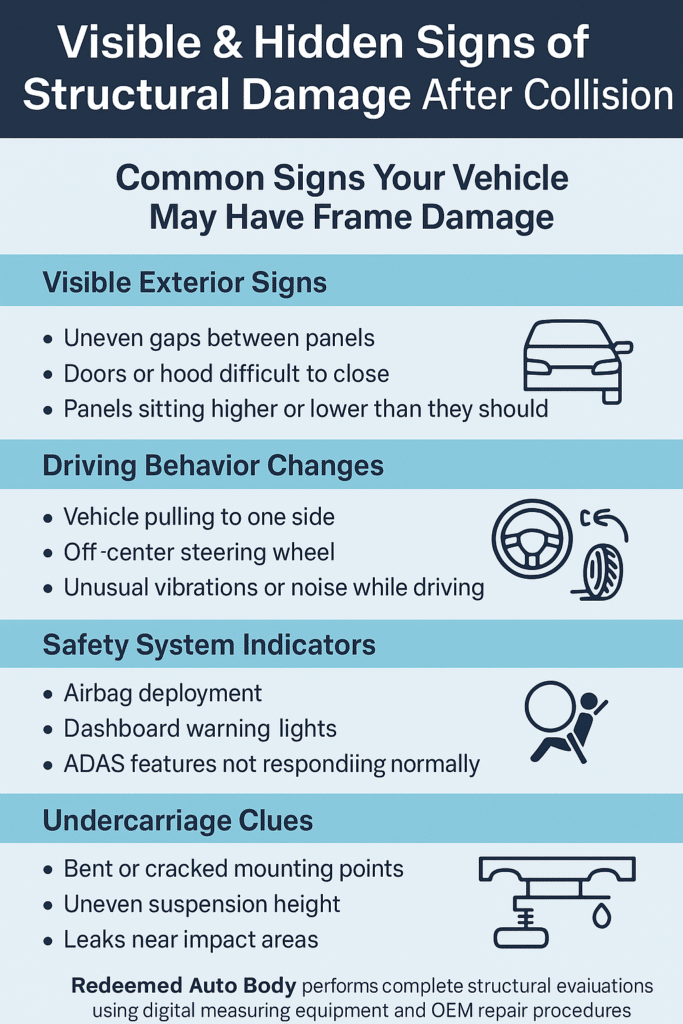

Signs Your Vehicle May Have Structural Damage

Some signs of frame damage are subtle, while others are easier to notice. If your vehicle shows any of these indicators after a collision, you should request a structural evaluation right away.

Uneven Body Gaps

If gaps between the hood, doors, or fenders appear inconsistent, the underlying mounting points may have shifted. Even slight variations can indicate structural distortion.

Vehicle Pulling or Drifting

A properly aligned vehicle should travel straight. Pulling, drifting, or difficulty controlling the car can signal structural irregularities affecting suspension geometry.

Panels That Don’t Align Correctly

If a door, hood, or liftgate does not close smoothly or appears out of place, the structure underneath may no longer be square.

Steering Wheel Off-Center

A crooked steering wheel after a minor collision is often connected to frame misalignment, not only suspension damage.

Airbag Deployment

Airbags deploy based on sensors mounted to the structure. If they deployed, the frame likely absorbed significant force.

Each of these issues requires more than a visual inspection. Structural misalignment can only be confirmed with precise measurements, which is why we rely on specialized equipment at Redeemed Auto Body to evaluate every hidden point in the frame.

Why Post-Accident Frame Inspections Protect Your Safety

Your vehicle’s safety systems rely on exact geometry to perform the way engineers intended. Even small shifts change how impact forces travel through the structure, which can place you at greater risk in a future collision.

Crash Protection

If the frame is misaligned, crumple zones may not activate correctly. Instead of absorbing energy in a controlled sequence, the force may transfer into the cabin. This raises the chance of more serious injuries.

Load Path Changes

Vehicle structures are engineered with load paths that distribute energy around the interior. Misalignment disrupts these paths and may cause components to collapse in unintended ways.

Dependence on OEM Engineering

Modern vehicles are designed with strict tolerances. A single deviation can affect how the vehicle performs under load. This is why frame inspections must follow OEM repair procedures.

At Redeemed Auto Body, we always follow factory repair procedures and never install aftermarket structural parts. We pull down OEM repair procedures for every vehicle and create a transparent repair plan that documents exactly what’s being done. Your safety depends on keeping the vehicle as close to original engineering as possible, and we take that responsibility seriously.

How a Modern Frame Inspection Works

Accurate frame inspection requires much more than looking at the outside of a vehicle. It involves diagnostics, digital measurements, and manufacturer-approved repair documentation. Here is how we handle every structural evaluation at Redeemed Auto Body.

Pre-Repair Evaluation and Digital Measuring

We begin by washing the damaged area to remove debris and reveal hidden issues. Next, we perform a complete pre-scan of all vehicle computers to identify fault codes and establish a baseline for the vehicle’s electronic systems.

Our Span measuring system records structural reference points across the frame using 3D measurement technology. This digital data tells us exactly how far the structure has shifted from factory specifications. Measurement accuracy is critical because even a small deviation can affect drivability and safety.

Comparing Measurements to OEM Specifications

After gathering measurement data, we compare every reading to the original manufacturer specifications. OEM repair plans guide our technicians step by step. This ensures the repair aligns with the vehicle’s original crash engineering.

We retrieve OEM procedures for every job. This is non-negotiable in our collision center because it ensures the vehicle returns as close as possible to its pre-accident condition while preserving its safety performance.

Documented Results for Insurance and Customer Transparency

We believe transparency builds trust. That is why we upload all repair documents, photos, and measurements into a dedicated folder for each customer. You can follow every step of your repair and understand exactly what was done.

We work with all insurance companies to manage claims, but our responsibility is to you. Our job is to advocate for the proper repair that your vehicle needs, not the least expensive option.

What Happens if You Skip a Frame Inspection After an Accident

Ignoring frame issues can cause long-term problems that affect both safety and daily driving. Over time, misalignment becomes more noticeable and more expensive to correct.

Here are a few consequences of skipping a structural evaluation:

- Premature Tire Wear: A misaligned frame alters suspension angles and shortens tire life.

- Suspension Issues: Components may sit at the wrong angles, causing vibrations or noisy operation.

- Compromised Crash Protection: If the frame is distorted, the car may not protect you the way the manufacturer intended.

- Improper ADAS Functioning: Radar, sensors, and cameras require precise alignment to operate correctly.

Structural problems also reduce resale value, especially for buyers who check service documentation. A vehicle with unresolved frame issues is harder to sell and may lose significant long-term value.

How OEM-Correct Frame Repairs Are Performed

A proper structural repair requires the right tools, training, and commitment to OEM standards. Our technicians follow a detailed process to correct misalignment safely and accurately.

We use a professional frame bench to secure the vehicle during the repair. This allows us to make controlled pulls that bring the structure back within factory specifications. Our shop uses industry-standard MIG and MAG welding systems, such as Pro Spot equipment. To meet manufacturer strength requirements, we follow OEM welding procedures, use the correct welding method for the material, and have trained technicians perform and document every weld.

We refuse to use aftermarket structural parts because they do not meet the same engineering criteria as OEM components. Our technicians hold I-CAR Platinum certifications, an advanced recognition that indicates they have completed extensive, role-specific collision repair training. This ensures they are trained in current structural repair methods and manufacturer procedures.

Our goal is simple. We want your vehicle to look, drive, and protect you exactly as it did before the accident. When the repair is complete, it should be undetectable.

Why Choosing the Right Collision Center Matters After Any Accident

Not every shop performs thorough frame inspections. Some shops focus on cosmetic repairs and do not invest in the measuring systems or OEM repair procedures required for structural accuracy. When searching for collision repair in West Monroe, LA, you need a shop that invests in precision measuring equipment and follows manufacturer repair procedures.

Many drivers assume that if a bumper or fender looks straight, the vehicle must be safe. Structural issues are not always visible. This is why choosing a collision center with the right equipment and training matters.

Redeemed Auto Body works independently from insurance DRP programs, which gives us the freedom to prioritize proper repair methods over cost-cutting. We keep you involved in every decision and help you understand how each part of the repair process contributes to your safety.

How We Complete a Full Post-Accident Structural Evaluation

Our collision repair process is designed to deliver transparency, accuracy, and vehicle safety.

Here is what you can expect:

- Pre-scans and Post-scans: We check all systems before and after the repair.

- Full Measurement Documentation: You receive access to photos, OEM procedures, and measurement reports.

- Prefitting Parts: We ensure proper alignment before painting.

- Color Matching: We use AkzoNobel color-matching camera and tools, combined with technician expertise, to achieve a close match to your vehicle’s original finish.

- ADAS Calibration: We coordinate calibrations with trusted dealerships when needed.

- Consistent Communication: We update you at least twice a week until the repair is complete.

- Lifetime Workmanship Warranty: Your repair is protected for as long as you own the vehicle.

These steps reflect our commitment to quality and your safety.

When You Should Request a Frame Inspection After a Collision

Not every accident is the same, but several scenarios always warrant a structural evaluation:

- Airbag deployment

- Front or rear impacts

- Side collisions

- Noticeable suspension changes

- Hitting a curb or pothole hard enough to feel a jolt

If you have any doubts, you should request an inspection. DIY assessments cannot reveal the full picture because frame issues are rarely visible from the outside. When in doubt, reach out to us so we can guide you through your next steps.

Post-Accident Frame Safety

Your vehicle’s structure is the backbone of its safety design. Ignoring frame misalignment can affect how the vehicle protects you and your family in a future collision. At Redeemed Auto Body, we take that responsibility seriously. Our goal is to repair your vehicle properly, restore its original safety performance, and give you complete confidence in the workmanship behind every repair.

Ready for Professional Collision Repair Services in West Monroe, LA?

If you have been in an accident, we are here to help. Our collision center provides comprehensive structural evaluations and collision repair services to drivers in West Monroe, LA, and nearby areas throughout northern Louisiana. Call us at (318) 789-6675 or email us at redeemedautobody@gmail.com to schedule a structural evaluation or ask questions about your repair options. We follow OEM procedures, provide transparent documentation, and work with all insurance companies, so you receive the proper repair your vehicle deserves.